Total sanitary controls for frozen food products

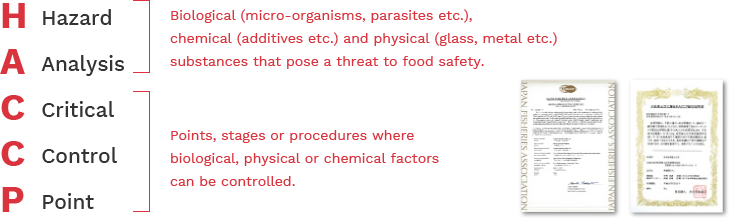

HACCP is an international standard for food safety. The quality of food products is one criteria of food safety. So what kinds of risks are there? Potential risks include food poisoning, contamination and other chemical hazards, including agricultural chemicals and drugs etc. HACCP was established with the aim to eliminate these hazards.

In comparison to conventional sanitary control methods, which placed an emphasis on inspection of the finished product (food product), HACCP aims to manage (analyze and identify potential hazards) critical stages in the production process in order to increase food safety and to identify processes or treatment methods from which these hazards can be eliminated or reduced to acceptable level, establish these as critical control points (CCP) and develop control standards (acceptable standards).

Working towards food safety

Food safety is a matter of international concern. Past incidents have proven that failure to implement proper food management can have a significant impact on everyday life, and in some cases can bring a profitable business to its knees. Overwhelming pressure from consumers, environmental groups and government bodies has forced players that form part of the food supply chain (namely manufacturers, catering industry, restaurants, hotels, food manufacturers, food distributors, retailers, food product storage providers, and pet food manufacturers etc.) to implement safer food management systems.

The hazard analysis and critical control point (HACCP) system is an international standard that defines the requirements of food safety management systems. Using the HACCP system allows organizations to identify hazards that will impact on food safety and sanitation, focus on critical control points among the food production processes and systematically define and establish acceptable limits. The HACCP system is based on the following seven principles.

Analyze biological, chemical or physical food hazards.

Identify critical control points in every facet of production, including raw materials, storage, processing, sales and consumption.

Establish critical limits and preventive measures for each critical control point. For example, defining the minimum cooking temperature and time etc.

Monitor critical control points.

Plan and establish corrective measures.

Systematic and periodical inspection of food management systems by an independent third party certification body.

Certification that your food management systems comply with the HACCP requirements provides the following advantages.

Promotes enhanced food safety and food safety management systems

Verifying that you are mindful of the production/trading of safe food products

Increased credibility in the eyes of consumers, retailers and government authorities

Enhanced brand/corporate image

Comes in handy when you are the subject of an audit by a regulatory body/ stakeholder

Increased opportunity to penetrate new markets and establish new clientele